Understanding Just How Plastic Nameplates Work: Insights Into Their Capability and Benefits

Plastic nameplates are vital tools for recognition and interaction in different settings. Built from durable products like acrylic and PVC, they offer both durability and visual appeal. Numerous printing techniques improve their presence and branding potential. Comprehending their capability discloses not just their functional applications however additionally the advantages they offer companies. As markets develop, the duty of plastic nameplates might shift, triggering a better look at their continuous importance and innovation.

The Products Behind Plastic Nameplates

Plastic nameplates are crafted from a variety of materials, each picked for its unique properties and suitability for various applications. Usual products include acrylic, polycarbonate, and PVC, each offering distinct advantages. Acrylic is preferred for its quality and light-weight nature, making it perfect for indoor use and display screen objectives. Polycarbonate, recognized for its high impact resistance, is frequently chosen for atmospheres where durability is important (Plastic Nameplates). PVC, on the other hand, offers a cost-efficient solution with good weather condition resistance, ideal for outside applications.Additionally, the option of product can affect variables such as shade retention, ease of printing, and general aesthetic allure. This option procedure warranties that the last product fulfills specific requirements, whether for branding, recognition, or attractive purposes. Understanding the homes of these products aids in making notified decisions when choosing plastic nameplates for numerous needs

Production Processes of Plastic Nameplates

The production processes of plastic nameplates encompass a number of vital actions that ensure high quality and resilience. Key elements consist of material choice strategies, various printing approaches, and ending up and covering options. Recognizing these elements is vital for producing reliable and aesthetically pleasing nameplates.

Product Choice Techniques

Selecting the best products for producing plastic nameplates is important for ensuring toughness, visual appeal, and functionality. Numerous plastic types are readily available, each offering distinct buildings matched for different applications. Polyvinyl chloride (PVC) is prominent for its price and resistance to ecological aspects, making it perfect for outdoor use. Acrylonitrile butadiene styrene (ABDOMINAL MUSCLE) provides enhanced impact resistance and is frequently picked for its remarkable strength and versatility. Furthermore, polycarbonate is preferred for applications requiring transparency and high influence resistance. The selection process entails taking into consideration variables such as the intended use, environmental direct exposure, and desired aesthetic high qualities. Eventually, careful product option greatly affects the performance and longevity of plastic nameplates, catering to diverse market requirements.

Printing Techniques Review

Product option prepares for the subsequent printing methods made use of in producing plastic nameplates. Numerous methods, such as screen printing, digital printing, and pad printing, are utilized to attain long lasting finishes and premium layouts. Display printing is preferred for its ability to generate vivid colors and is suitable for large runs. Digital printing, on the other hand, provides flexibility and precision, making it optimal for smaller sized orders with variable information or complex styles. Pad printing permits the transfer of photos onto irregular surface areas, suiting intricate shapes. Each printing approach adds distinctly to the final item's appearance and longevity, making sure that the nameplates properly share the designated message and endure ecological variables.

Ending Up and Covering Options

Ending up and layer alternatives play a vital role in boosting the durability and visual allure of plastic nameplates. Various techniques, such as UV finishing, offer a safety layer that stands up to scratches and fading, greatly prolonging the product's lifespan. In addition, laminating flooring options can supply a matte or glossy finish, permitting customization to match branding demands. Anodizing and electroplating are likewise prominent approaches, adding a metal luster while improving rust resistance. These finishings not only enhance look however also add to the nameplate's performance by safeguarding versus ecological aspects. Moreover, specialized surfaces, such as anti-graffiti finishes, guarantee that nameplates keep their clarity and aesthetic appeal in difficult problems. The ideal finishing and finishing selections can greatly boost the total worth of plastic nameplates.

Layout Options for Personalization

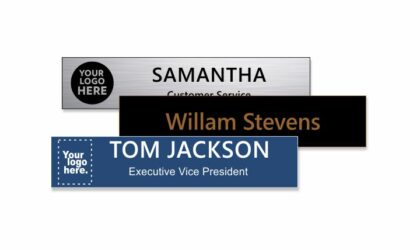

While discovering design options for customization, one discovers a vast range of opportunities that can improve the visual and functional appeal of plastic nameplates. Color selection is a primary factor to consider, as vibrant shades can draw in attention while neutral shades promote professionalism and reliability. Numerous font style options and sizes in addition individualize nameplates, ensuring legibility and alignment with brand identity.Incorporating logos or photos adds a distinctive touch, strengthening organizational branding. Form personalization permits for unique layouts, varying from conventional rectangles to more intricate kinds, catering to specific motifs or environments.Textures such as matte or glossy coatings can likewise influence the total appearance, providing a responsive dimension. Additionally, the combination of decorative elements like boundaries or backgrounds improves aesthetic rate of interest. These customization alternatives jointly make it possible for organizations to develop plastic nameplates that properly communicate their identification and message while meeting sensible needs.

Durability and Long Life of Plastic Nameplates

Although several elements influence the sturdiness of plastic nameplates, the option of material and production procedures plays a substantial duty in their longevity. High-grade plastics, such as polycarbonate and acrylic, are frequently chosen for their integral resistance to weather, uv, and effect radiation. These materials can withstand extreme environmental problems without considerable degradation, ensuring that nameplates remain intact over time.Furthermore, progressed production methods, such as shot molding and laser engraving, add to the effectiveness of plastic nameplates. These processes create accurate and resilient inscriptions that withstand fading and wear. Additionally, safety finishings might be related to enhance resistance to scrapes and chemicals, even more expanding their lifespan.Ultimately, the mix of top quality products and effective production processes assures that plastic nameplates maintain their performance and look for years, making them a reputable selection for numerous applications.

Applications Across Different Industries

Plastic nameplates serve a range of necessary features throughout various industries. They are frequently utilized for commercial tools recognition, guaranteeing clear labeling for safety and security and operational effectiveness. Furthermore, they supply effective workplace signs options and play a vital function in security and conformity markings, highlighting their adaptability and relevance in diverse environments.

Industrial Tools Recognition

Reliable industrial devices recognition is vital throughout various sectors, as it assures safety and security, effectiveness, and conformity with regulatory criteria. Plastic nameplates function as a vital device in this process, offering resilient and clear identification for equipment and tools. Industries such as building and construction, production, and power use these nameplates to display essential details, consisting of running guidelines, hazard warnings, and maintenance routines. Their strength to extreme environments warranties that vital data remains available, minimizing the danger of accidents and operational downtime. In addition, customizable attributes permit branding and details identifying requirements, making plastic nameplates flexible across applications. On the whole, reliable tools recognition with plastic nameplates cultivates a safer workplace while improving performance in diverse industrial setups.

Workplace Signs Solutions

In various industries, the value of clear communication prolongs beyond industrial equipment to office settings where signs plays an essential function. Plastic nameplates work as effective office signage services, giving vital details such as employee names, job titles, and department classifications. These nameplates improve professionalism and promote a welcoming atmosphere, helping both personnel and site visitors in navigating the work area. In addition, they provide modification options, permitting services to line up signs with branding and aesthetic preferences. In settings like healthcare facilities, universities, and corporate workplaces, clear and resilient signage assurances effective interaction and contributes to business efficiency. Ultimately, making use of plastic nameplates in workplace atmospheres not just improves quality but additionally advertises a natural and well organized work area.

Security and Conformity Markings

While many companies focus on visual appeals and branding in their safety and security, signs and compliance markings are just as important across read this article numerous markets. These markings work as important devices for communication, assuring that staff members and customers understand prospective dangers, security methods, and governing requirements. In manufacturing, as an example, plastic nameplates typically display advising tags and usage directions to minimize risks. In medical care, compliance signage educates personnel concerning hygiene techniques and equipment use, thus advertising a risk-free atmosphere. Additionally, the durability of plastic nameplates makes them appropriate for different setups, resisting deterioration from environmental factors. Overall, security and conformity markings enhance functional effectiveness, promote wellness, and warranty adherence to sector standards, making them indispensable in modern offices.

Advantages of Making Use Of Plastic Nameplates

Numerous advantages make plastic nameplates an attractive choice for companies and services. One primary advantage is their longevity; plastic nameplates are resistant to fading, moisture, and various environmental aspects, guaranteeing durability in diverse setups. Additionally, they are lightweight, making them easy to transfer and mount as needed.Cost-effectiveness is an additional significant advantage. Plastic nameplates generally call for lower manufacturing prices compared to steel or timber choices, allowing organizations to keep budget plans while see this website accomplishing specialist branding. Their convenience also sticks out, as they can be tailored in different shapes, sizes, and colors to match branding requirements.Furthermore, plastic nameplates can be conveniently published with high-resolution styles, promoting clear visibility and reliable interaction. They are frequently made from recyclable products, lining up with environmentally aware techniques. These mixed benefits enhance the capability and charm of plastic nameplates for an array of applications in different markets.

Tips for Selecting the Right Nameplate for Your Requirements

Choosing the appropriate nameplate can significantly improve an organization's branding and communication efforts. To make an informed decision, one must first consider the product. Plastic nameplates supply durability and versatility, making them ideal for various environments. Next off, examine the style facets, including dimension, shade, and font design, guaranteeing they align with the company's branding guidelines.Additionally, it is essential to examine the desired use of the nameplate. For instance, if it requires to endure exterior conditions, picking UV-resistant choices is advisable. Personalization is another vital aspect; personalized nameplates can show uniqueness and professionalism.Lastly, budget factors to consider ought to not be forgotten. Comparing prices across various vendors while considering high quality will certainly assist in locating a suitable solution. By taking these components right into account, companies can choose a nameplate that effectively interacts their identification and function.

Regularly Asked Concerns

Can Plastic Nameplates Be Recycled After Usage?

Plastic nameplates can be recycled, relying on the sort of plastic utilized and local reusing centers. Correct disposal and recycling practices add to ecological sustainability, motivating the decrease of plastic waste in garbage dumps.

Exactly how Do I Clean and Maintain My Plastic Nameplate?

Are Plastic Nameplates Waterproof or Water-Resistant?

Plastic nameplates normally exhibit water-resistant buildings, safeguarding them from minor moisture exposure. Nonetheless, prolonged submersion or extreme problems may compromise their honesty. Plastic Nameplates. Users should consider details materials and finishes for boosted waterproof abilities when picking nameplates

What Is the Average Lifespan of a Plastic Nameplate?

The average life-span of a plastic nameplate generally ranges from 5 to 10 years, depending upon elements such as environmental exposure, material high quality, and maintenance. Routine treatment can prolong its functionality and look considerably.

Can I Order a Nameplate in a Specific Shape?

Custom shape options for nameplates are frequently offered via numerous makers. Clients can ask for particular layouts, more making certain that the nameplate fulfills their visual and practical demands while keeping resilience and quality throughout its lifespan. Product option lays the foundation for the succeeding printing methods used in generating plastic nameplates. Several aspects influence the sturdiness of plastic nameplates, the option of material and production procedures plays a significant duty in their durability. These materials can withstand rough ecological conditions without substantial deterioration, assuring that nameplates continue to be intact over time.Furthermore, progressed production techniques, such as injection molding and laser inscription, add to the robustness of plastic nameplates. Plastic nameplates can be reused, depending on the kind of plastic made use of and regional recycling centers. The average life-span of a plastic nameplate commonly varies from five to ten years, depending on aspects such as environmental direct exposure, material top quality, and upkeep.